Since its creation, FIGENER has performed autonomous industrial measurement services with highly qualified technical personnel in the areas of energy, process and electrical.

With Field Measurements, FIGENER is able to quickly and conclusively identify customers operational deficiencies, locating potential savings and optimizing processes / energy efficiency.

We can do:

Measurements of pressure, flow and temperature of fluids (gases and liquids):

- Pitot Prandt, Pitot "S", for ducts from 100mm to 6000m. In many cases, we ask the customer to drill the pipelines at strategic points so that the measurement can be carried out.

- Anemometer.

- Ultrasound.

- Orifice plate.

- Temperature with datalogger and PT100 sensor (for cooling water for towers).

- Suction pyrometer.

- Temperatures - TBS / TBU.

- Analysis of flue gases in furnaces, ovens and boilers.

- CO, O2 and NOx analysis.

- Survey of mass and energy flows (mass and energy balance).

- Tests on industrial equipment (boilers, fans, cooling towers, etc.) and performance verification.

- Evaluation of combustion systems.

- Evaluation of cooling towers (flow measurement, water temperatures, TBS / TBU and air flow).

- Electrical electrical measurements.

- Quality of electricity - QEE related to new accesses to the Basic Network.

- Voltage, Current, Power Factor, Harmonics.

- Soil resistivity.

Measurement services are essential tools that provide important inputs in the evaluation of industrial processes, ensuring precision in technical diagnostics and energy efficiency studies.

Some references:

- 2018 - Various measurements in the Mines and Zinc Ore Processing Plant (MILPO-Nexa - Peru).

- 2017 - Flow and Temperature Measurements of Chilled Water and Cooling Water Plants (Mondelez-PR).

- 2013 - Flow Measurements in Braskem Cooling Water System - UNIB 3.

- 2009/2011 - Pelletizing Furnace Fans and Ducts (VALE-ES).

- 2008 - Iron-Nickel Dryer Exhaust Gas Ducts (Codemin Anglo American-GO).

- 2004 to 2007 - Various Measurements for Energy Efficiency Studies in several Votorantim units (Barra Mansa, Acerbrag, Citrovita, Niquelandia, Tres Marias, Serra da Fortaleza).

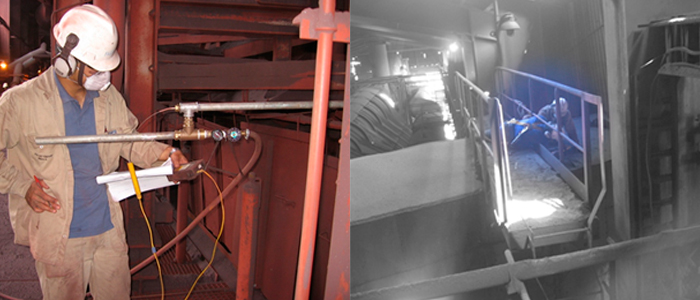

The images above show:

1. Flow measurement in hot gas ducts in VALE Furnaces. Flow rate @ 400 ° C was measured in ducts up to 4m wide and chimneys of 6 m in diameter with the aid of pitot S adapted by Figener. The measurements served as a basis for the analysis of the Energy Efficiency Study of the Furnaces.

2. Gas temperature measurement in the final region of one of Vales ovens. Temperature measurement at around 400 ° C, using a suction apparatus (ejector type, of own manufacture) to eliminate the effect of radiation from the pellets.

3. Pre-measurement moment in an underground mine located in Peru. Several measurements were made in the mines ventilation system: electrical measurements, differential pressure measurements, and survey of speed profiles in the tunnels (up to 6m in diameter) using blade anemometers. At the time, measurements were also made on the mine water extraction pumps, with surveys of electrical data, flows and pressures.

4. Flow measurement using an ultrasound meter in the pipeline of a SHP located in Peru.