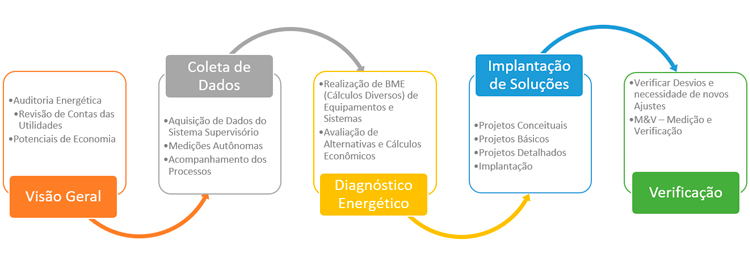

With a completely independent team of suppliers, Figener can carry out energy efficiency studies in several industrial and energy sectors. Studies can be divided into the following steps:

For whom the study is recommended:

Industries from the most diverse branches containing:

- Furnaces / Dryers / Boilers of the most diverse types.

- Complex Cool Water and Cooling Plants.

- Pumping / Ventilation Systems.

- Steam Systems.

- Cogenerations.

- Thermoelectric Plants.

- Shopping Centers (Malls, Large Commercial Buildings), usually HVAC / cogeneration systems.

When:

- New industries (during the projects, many equipments are oversized, making them operate in points with low inefficiency).

- Industries with more than 10 years of operation (usually with more obsolete equipment).

- Installations where production has been reduced.

Objectives:

- Retrofit Assessment of Existing Equipment.

- New Equipment Installation Evaluation.

- Evaluation of Fuel Replacement.

- Reduction of Atmospheric Emissions and / or Effluents (liquid and solid).

FIGENER differentials:

- Figener is a company totally free of suppliers or technologies. Thus, the studies are not focused on selling equipment or systems.

- The calculations are performed with a global view of the process, not just checking the impact of a certain equipment. Example: for cogeneration studies, FIGENER develops models for the entire cycle (boiler / turbine / reducers / pumps) to calculate savings.

For that, FIGENER has:

- Specialists who perform BMEs (mass and energy balances) customized for each system.

- Adequate tools to aid calculations (PowerFNESS, FNESS and various spreadsheets).

- Figener is prepared to perform highly complex measurements.

- Data analysis in order to evaluate different operating conditions (low / medium / high load).

References:

- MRN (Evaluation of the Ore Drying System - Burning System / Fans / Gas Treatment System).

- Ingredion / Corn Products (Dryers evaluation).

- Firmenich (evaluation of Spray Dryer and Odor Incinerator).

- Vale (efficiency study of Pelletizing Furnaces).

- Several Votorantim units (Niquelândia, Três Marias, Acerbrag, Barra Mansa, Citrovita Araras / Catanduva).

- Nitro-chemistry (evaluation of several systems and processes, including cogeneration).

- Suzano Fabrica B (evaluation of several processes).

- Mosaic Uberaba (study on the steam system).

- Mondelez Curitiba (evaluation of the cold water / hot water / steam system).