Combined with solid theoretical knowledge, FIGENER team has extensive experience, having performed dozens of analyzes and projects throughout its history. FIGENER is able to specify, design, analyze or propose reforms for various industrial equipment and systems, such as: calciners, washers, vacuum systems, pumping systems, boilers, burners, furnaces, heat exchangers, etc.

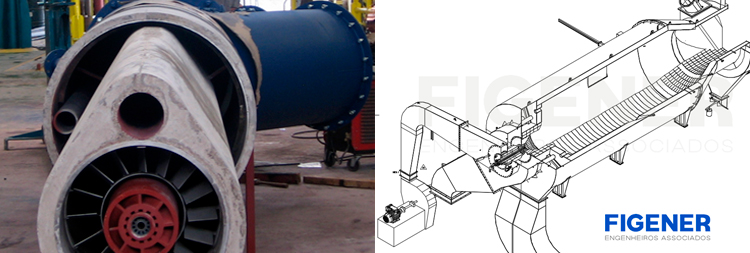

FURNACES:

In these projects, we seek to obtain an optimized solution in terms of materials used and dimensions, in order to reduce costs, while guaranteeing the full development of flame, cenospheres (unburned particles) and low external temperatures .

A normally envisaged requirement is the long duration of the materials used, making, therefore, a judicious selection of materials according to the characteristics of the fuels and the levels of excess air expected in the burning.

In case of renovation of existing equipment, FIGENER carries out projects aiming at improvements such as increasing capacity and reducing maintenance.

Among the references of projects carried out by FIGENER, is:

- Hot Gas Combustion Chamber Project for STPP Calciner - Columbian.

- Fuel: tail gas (PCI 846 kcal / Nm³) and natural gas.

- Capacity: 4 Gcal/h.

- Hot gas temperature: up to 900 °C.

- Renovation of the Bauxite Dryer Furnace.

- Fuel: Heavy Oil.

- Capacity: 23 Gcal/h.

- Operating Temperature: 1200 °C (design 1500 °C).

BURNERS:

FIGENER develops burner designs for various fuels such as natural gas and process waste gases.

Projects can be either:

- Adaptation of pre-existing burners.

- Expansion of capabilities.

- Replacement of fuels.

- Completely new equipment.

REFERENCES:

- Burner Project for Burning Natural Gas and Poor Gas.

- Equipments served: 2 steam boilers (25 and 12 t/h) with a capacity of: 18 Gcal/h and 11 Gcal/h respectively).

- XXX Oil Burner for Nickel Iron Dryer.

COMBUSTION SYSTEMS:

In these studies, all components of a fuel and air supply system, combustion chambers and burners are addressed, in general and analytically, aiming at the following aspects:

- Combustion optimization.

- Quality of flame and combustion.

- Controllability.

- Security.

Examples of work done:

Study of the combustion systems of five steam boilers of 400 t/h, 120 kgf/cm², 535 °C, with a view to suggesting changes to increase combustion quality.

BOILERS:

The studies and projects aim to solve the problems typically presented in boilers, such as pipe breaks and production below the nominal. Some of the services that can be performed are:

- Study of the origin of the pipe corrosion process.

- Study and project for elevating natural circulation.

- Flow analysis in steady state.

- Flow analysis in load and pressure transients.

- Flexibility calculations.

- Support in discussing the tube-to-tube exchange alternative for in-bed evaporators.

Examples of work done:

Study and Project for recovery of CFB type boilers of 240 t/h of superheated steam @ 95.8 bar abs / 485 °C.

EXHAUST SYSTEMS AND GAS TREATMENT:

The design of gas treatment and systems covers a wide range of applications, ranging from local dedusting to exhausting hot gas dryers.

The purpose of these studies is to meet the flows required by the processes and / or the elimination of polluting substances at the level required by the environmental control bodies.

Some outstanding projects of this nature:

- Exhaust system and gas treatment (absorption with NH3 with acidic solution) effluents from ammoniated fertilizer granulator.

- Exhaust system and gas treatment of isolated points in a fertilizer plant.

- Exhaust system and treatment of Ferro-Nickel calcining furnace gases.

FIGENER also has experience in systems that burn fuel with a sulfur content.

Executive project to install dampers with double flap and sealing system (fans).

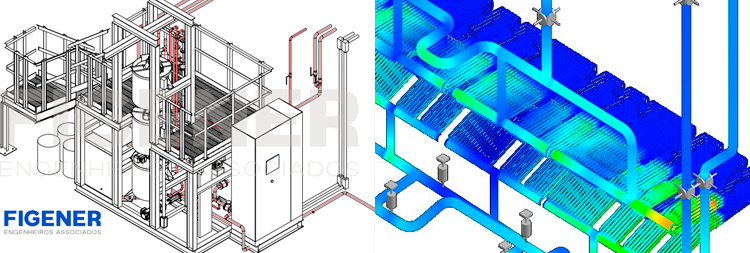

SPECIAL EQUIPMENT:

Figener can carry out projects of skids / modules of industrial equipment totally customized.

The project includes the elaboration of process and engineering flowcharts, descriptive memorials, technical specifications of equipment / automation / assembly, data sheet of the components and list of materials.

In addition to these engineering documents, various drawings are made (3D models, arrangements and general cuts, isometric piping) that allow an easy understanding of the equipment.