Combined with solid theoretical knowledge, FIGENER team has extensive experience, having performed dozens of analyzes and projects throughout its history. FIGENER is able to specify, design, analyze or propose reforms for various industrial equipment and systems, such as: calciners, washers, vacuum systems, pumping systems, boilers, burners, furnaces, heat exchangers, etc.

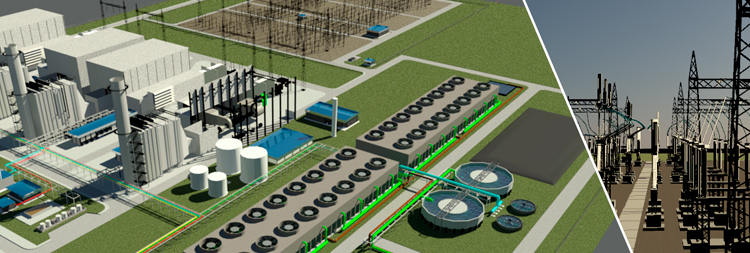

In addition, FIGENER carries out conceptual and basic projects for power and utility plants, evaluating the best solution for the customer. You can also perform Engineering support to the Customer, giving necessary support for the projects to be executed properly.

Some important projects in which FIGENER participated:

- Renovation of CFB Boiler (250 t/h @ 95 bar / 485 °C);

- Renovation of large-scale furnaces and stoves;

- Thermoelectric Power Plant Projects of the most diverse;

- Biomass Boiler Installation Projects.