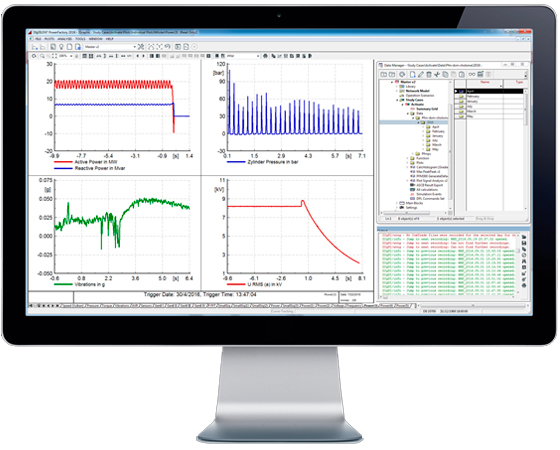

State of the art system in the calculation of power systems. Allows calculations of load flow, short-circuit, harmonics, electromechanical and electromagnetic transients, overcurrent and distance protection and reliability, all on the same database, totally object oriented and generalized for mono, bi and three-phase systems, CC up to CA 1 kHz.

FIGENER Systems is the company that exclusively sells DIgSILENT PowerFactory software in Brazil and provides the necessary training for beginners in the use of this powerful tool.

The development of the program started in 1976, and used the talent and experience of engineers and programmers with extensive experience directly involved in the planning, operation and maintenance of power systems. Its first commercial version was launched in 1983. In 1995 the program was completely re-engineered to incorporate more modern software technologies, improved algorithms, object-oriented database and 100% MS Windows compatible graphic interface.

Since then, the program has been setting new standards for the market in terms of integration and modeling flexibility, which has won companies from the most diverse sectors worldwide. There are currently more than 6000 licenses for use in more than 100 countries. In Brazil, the program has been in the market for more than 15 years, and with that the program has licenses installed in companies such as industries, concessionaires, engineering companies, universities and research institutes. All support and training can be provided in both Portuguese (local) and English (Germany).

For more information visit the official page of DIgSILENT